¶ Defocus Occurs at Specific Work Area Locations While Other Areas Remain Normal

¶ Problem Discription

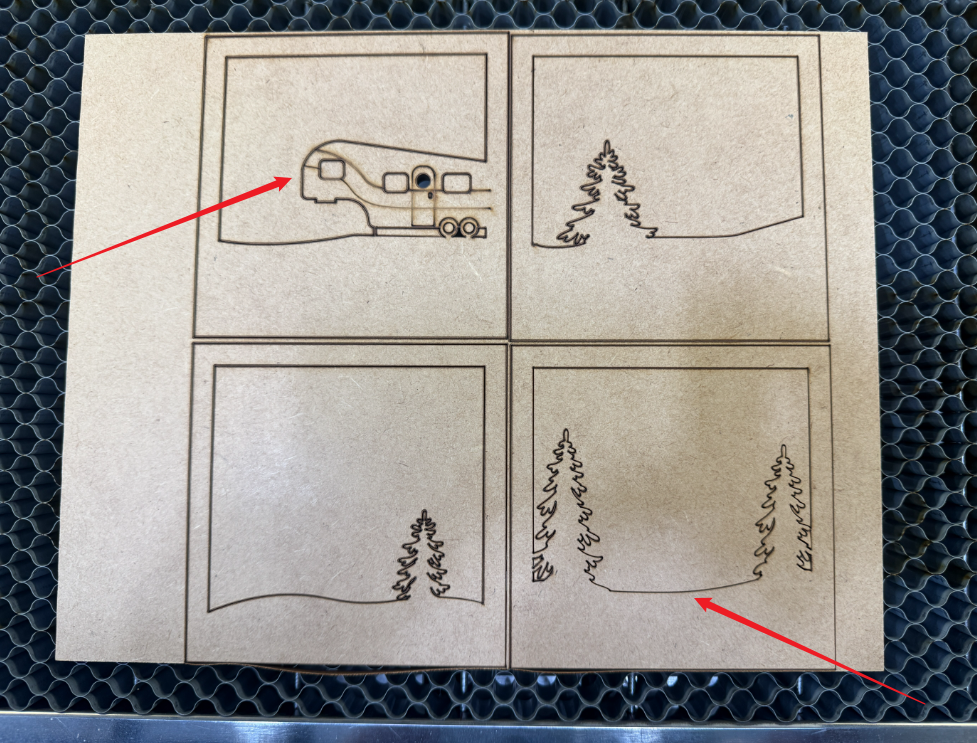

When the laser head is processing in a specific area of the work zone, the cut line widens and carbonization occur. However, processing results in all other areas of the workbed are normal.

¶ Cause

- If the issue becomes progressively worse the further the laser moves to the right: This could be due to beam path misalignment or an unlevel working platform.

- If the issue primarily appears on the left side: This is most likely caused by an unlevel working platform.

¶ Solution

Check and Level the Working Platform:

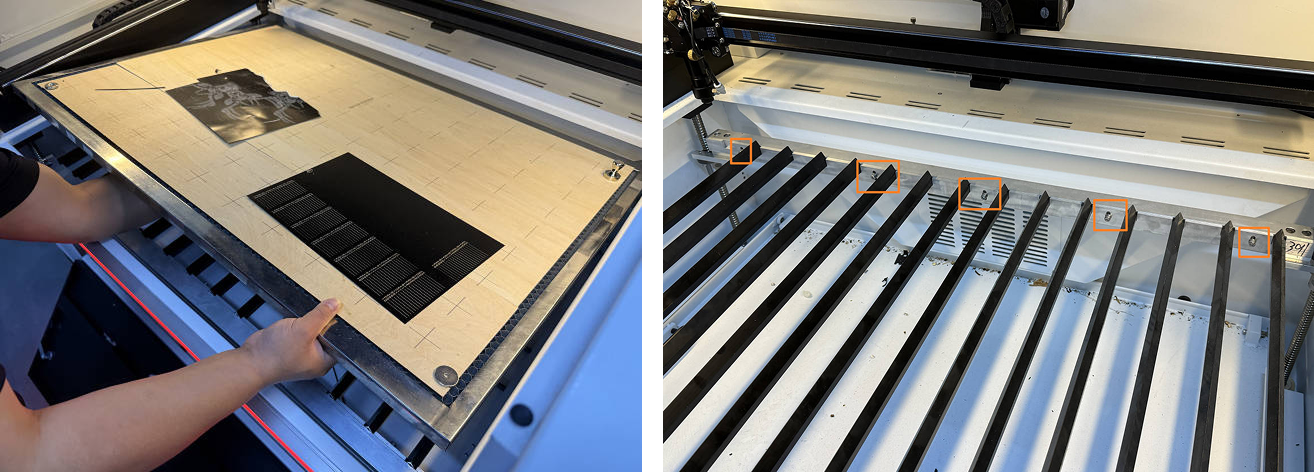

- Check the distance between the cone tip and the working platform at various points. If the distance from the cone tip to the platform is inconsistent in the problematic area compared to other areas, the working platform is unlevel.

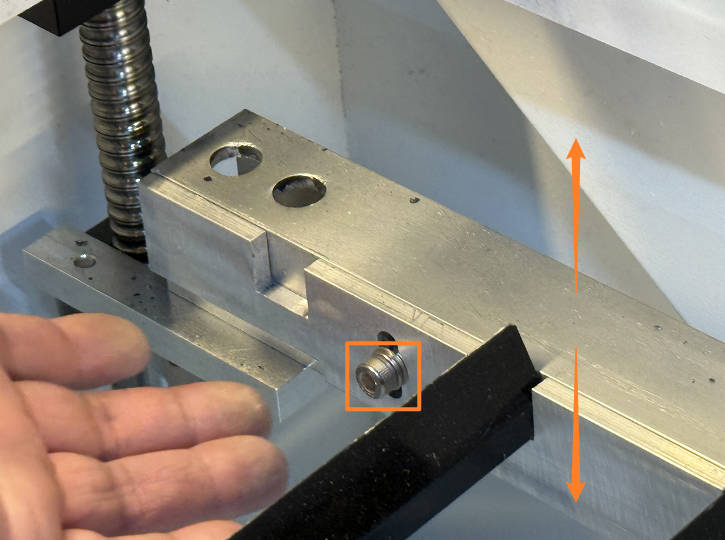

- Remove the honeycomb panel. You will see two metal bars (front and back) that hold the knife-edge slats; each bar has five screws.

- Loosen the screws located beneath the area where the processing/distance measurement issue occurred. Use your hand to slightly lift or push down the metal bar to finely adjust the horizontal angle of the entire working platform. After the adjustment, be sure to tighten the screws and reinstall the honeycomb panel.

Check for Beam Path Misalignment:

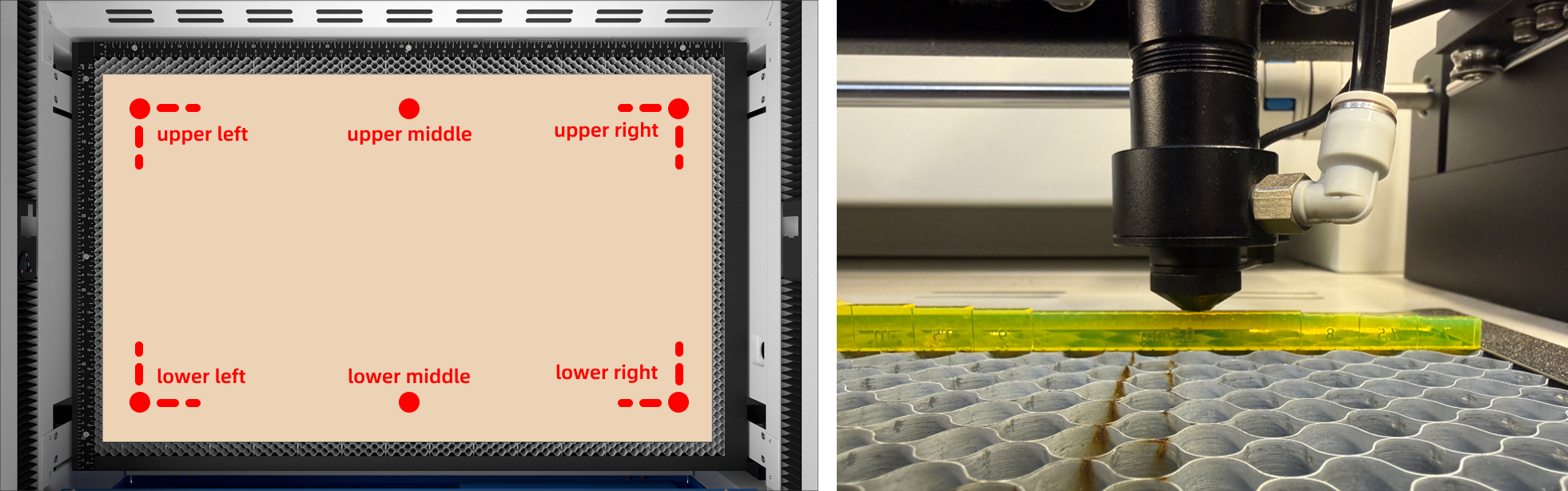

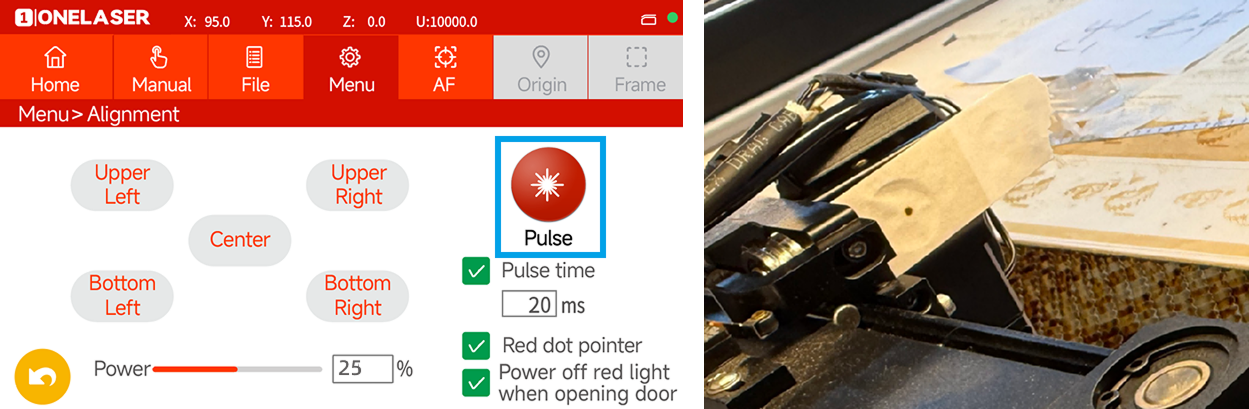

- Place tape on the mirror mount at the laser head. Move the laser head to the four corners of the working platform (top-left, bottom-left, top-right, bottom-right). Then, tap the Pulse button on the control panel at each corner to leave a burn mark on the tape.

- Observe whether the four burn marks overlap and are centered. If the burn marks do not overlap, it indicates beam path misalignment, and you will need to calibrate the laser path.

Important Reminder:

If these steps do not resolve the issue, please click this link to submit a support ticket. A technician will then be able to conduct a more in-depth diagnosis and resolve your problem.