¶ Hydra Series Maintenance

¶ 5.1 Cleaning the Laser Machine

Caution – use of controls or adjustments or performance of procedures other than those specified here in may result in hazardous laser radiation exposure.

Before starting cleaning and maintenance work always switch off the device and unplug the mains plug.

Always keep the system clean, as flammable parts in the working area or exhaust area rise the fire hazard.

You should check at least once a day, whether dust has accumulated in the engraving system. In case of soiling the machine must be cleaned. The cleaning interval strongly depends on the material that is being processed and the operating time of the device. Please bear in mind that only a clean machine guarantees optimal performance and reduces the service costs.

General Cleaning Notes:

1. Make sure, that the device is switched off and unplugged. Open the protective cover.

2. Move the working table into a position in which it is easiest for you to clean the surface with a window cleaning agent and paper towels.

3. Thoroughly remove all loose dirt particles and deposits in the interior of the machine.

4. Clean the cover of the laser tube.

5. You can clean the viewing window with a cotton cloth. Do not use paper towels as they could scratch the acrylic.

6. The laser nozzle should be cleaned regularly to prevent oil and grease buildup from obstructing the laser beam. It is recommended to clean the laser aperture every three days.

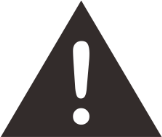

¶ 5.2 Cleaning the Optical Parts

The lens has a durable multi-coating and won’t be damaged by correct and careful cleaning. You should inspect the focus lens and the mirrors and the beam combiner according the maintenance plan. If you discover a veil of haze or dirt, you must clean them.

It is suggested to clean the mirrors/lens before work every day in order to run the machine at max efficiency.

Please turn off the power of laser machine before cleaning the optical parts.

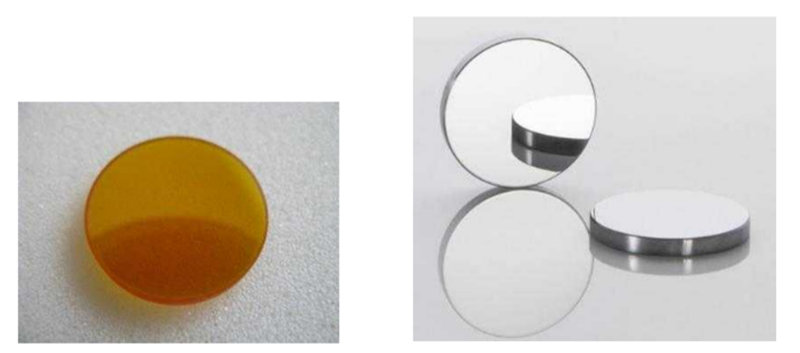

1. The cleaner and cotton swabs are in the tool box that came with the machine.

2. The lens must be cleaned carefully with a clean cotton swab to avoid scratching the surface of the lens.

3. Do not touch the lens with your hands after wiping.

4. Never use a cleaning swab twice.

Follow the instructions below for the cleaning of optical parts:

¶ 5.2.1 Cleaning the Focus Lens

1. Move the working head into the center of the working surface.

2. Take the lens out.

3. Remove the coarse dust as good as possible by blowing air onto the lens surface.

4. Clean the lens with the cleaner and swabs.

5. Finally, dry this side of the lens with dry cleaning swabs and repeat the cleaning process on the other side of the lens. Never use a cleaning swabs twice. Dust accumulated in the cleaning swabs could scratch the lens surface.

6. Examine the lens. If it is still soiled, repeat the cleaning process until the lens is clean.

7. Install the lens back.

¶ 5.2.2 Cleaning the Mirrors

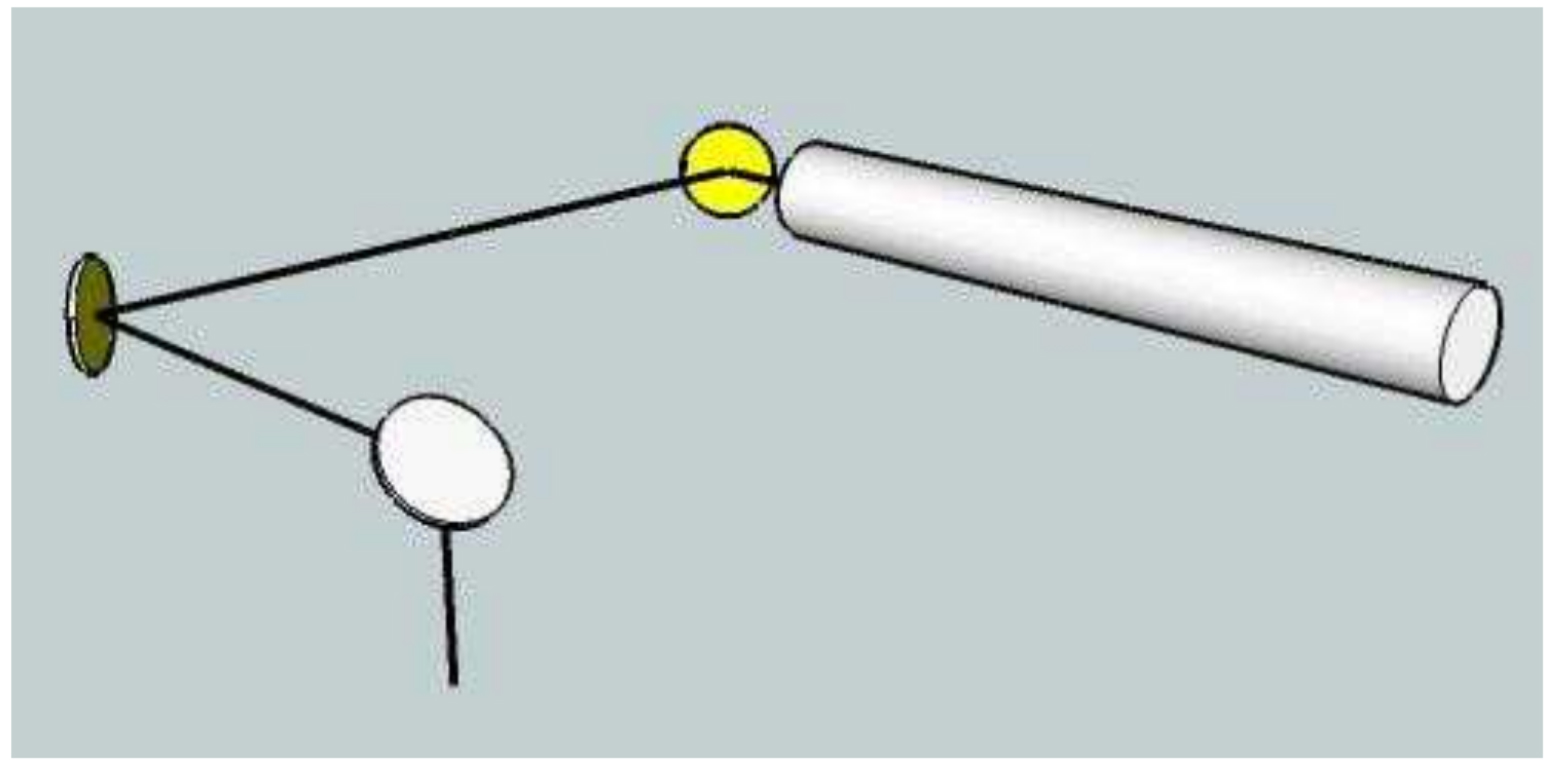

There are three mirrors in the operating area of the laser, which may have to be cleaned if they are soiled. To clean the reflector, follow the instructions below.

1. Remove the coarse dust as good as possible by blowing air onto the mirror surface.

2. Clean the lens with the cleaner and swabs.

3. Finally, dry this side of the mirror with dry cleaning swabs and repeat the cleaning process on the other side of the mirror. Never use a cleaning swabs twice. Dust accumulated in the cleaning swabs could scratch the mirror surface.

4. Examine the mirror. If it is still soiled, repeat the cleaning process until the lens is clean.

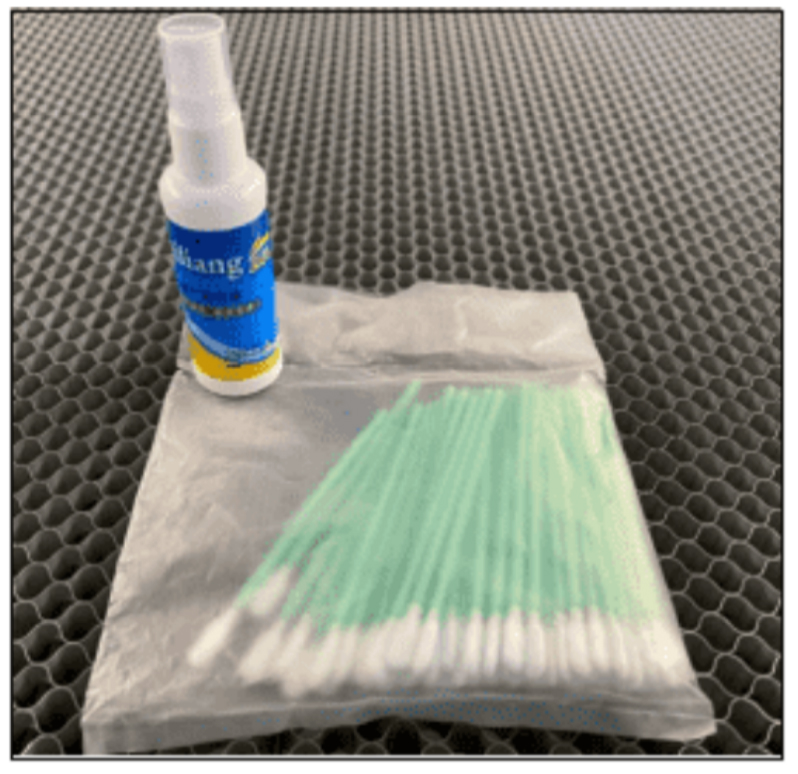

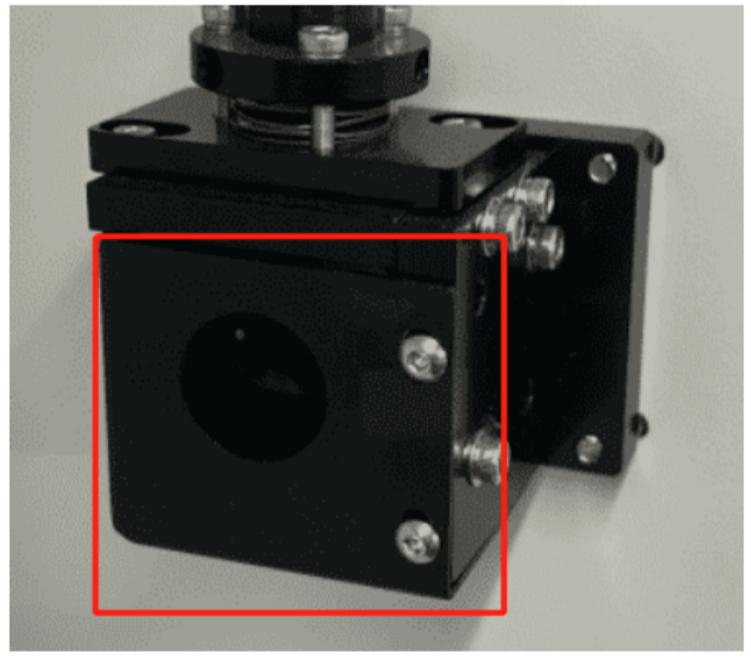

¶ 5.2.3 Cleaning Laser Combiner

1. The laser combiner is installed on the left side of the first mirror.

2. Remove the coarse dust as good as possible by blowing air onto the combiner surface.

3. Clean the lens with the cleaner and swabs.

4. Finally, dry this side of the laser combiner with dry cleaning swabs and repeat the cleaning process on the other side of the lens. Never use a cleaning swab twice. Dust accumulated in the cleaning swabs could scratch the combiner surface.

5. Examine the laser combiner. If it is still soiled, repeat the cleaning process until it is clean.

¶ 5.3 Check the Beam Path

After being used for a long time, the beam path might be deflective. This will reduce the efficient of the laser beam or even cause no laser beam. At this moment, you will need to re-adjust the beam path again.

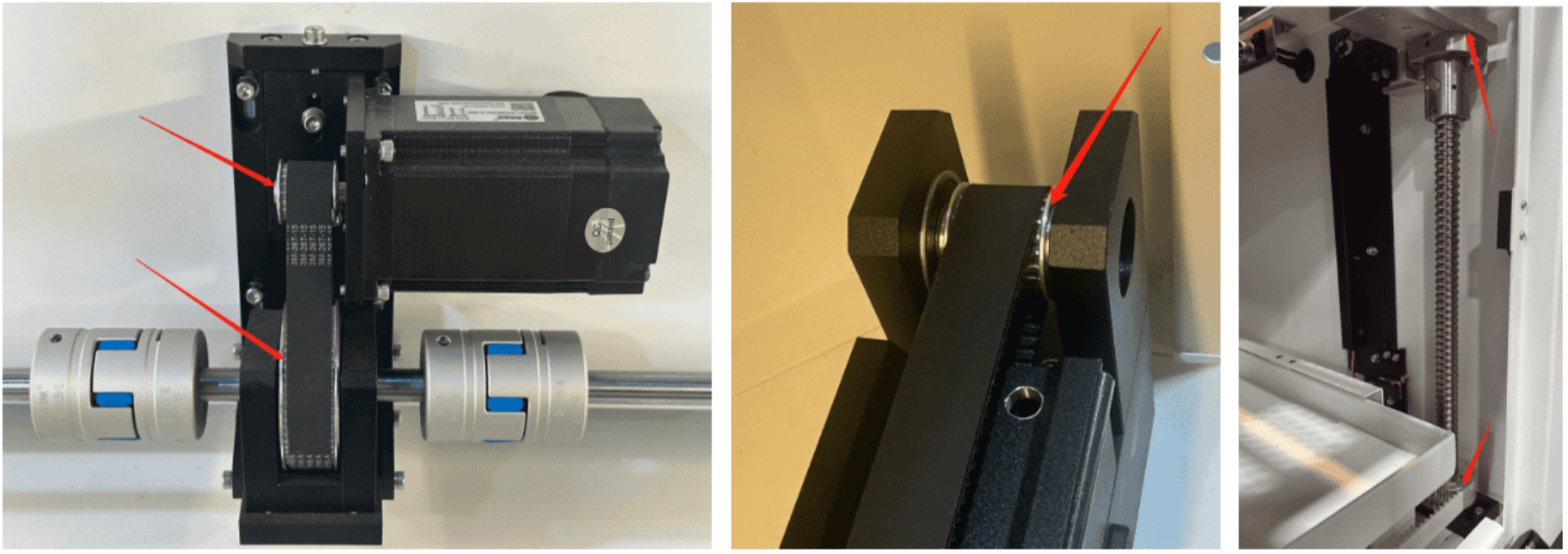

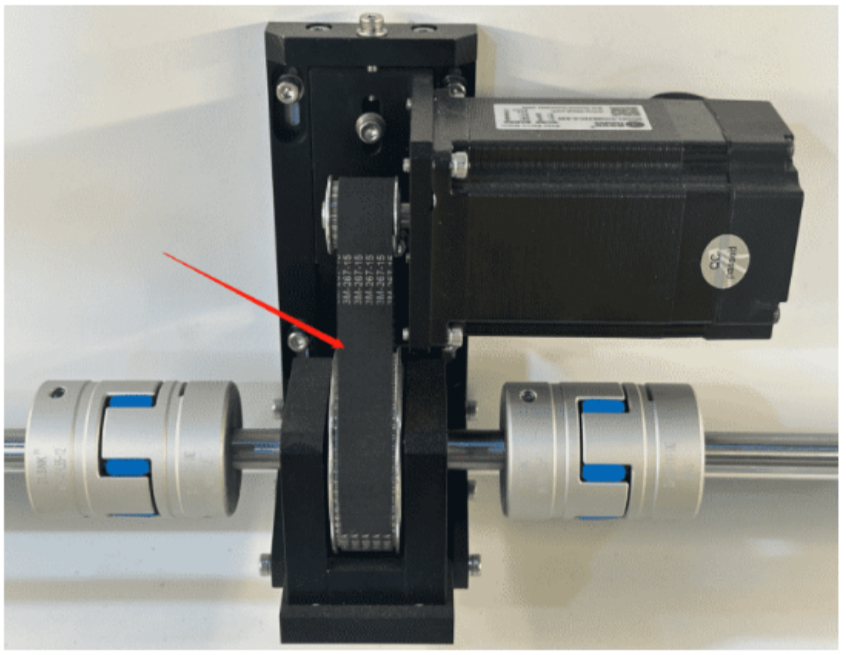

¶ 5.4 Cleaning the inside of the machine

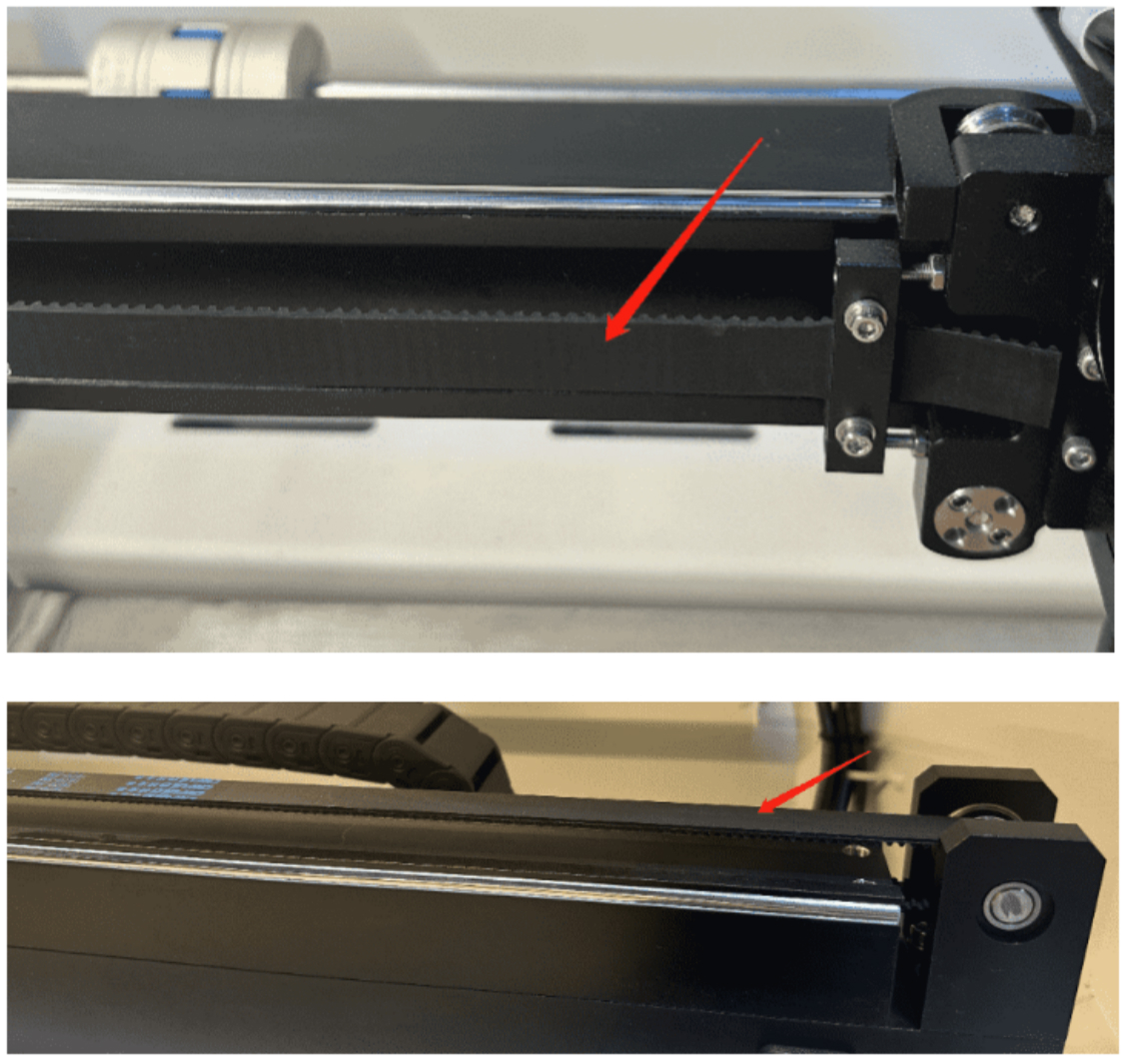

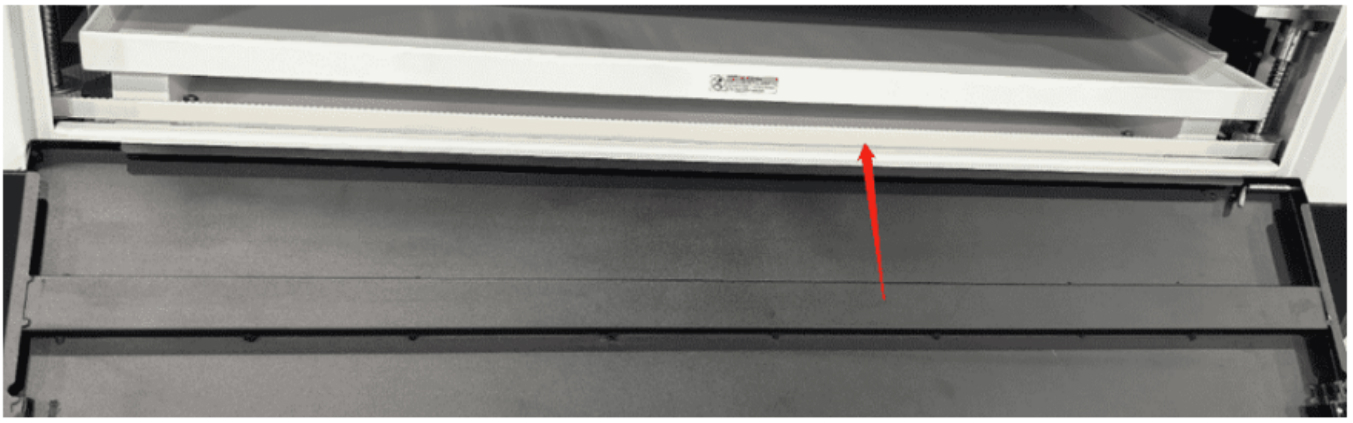

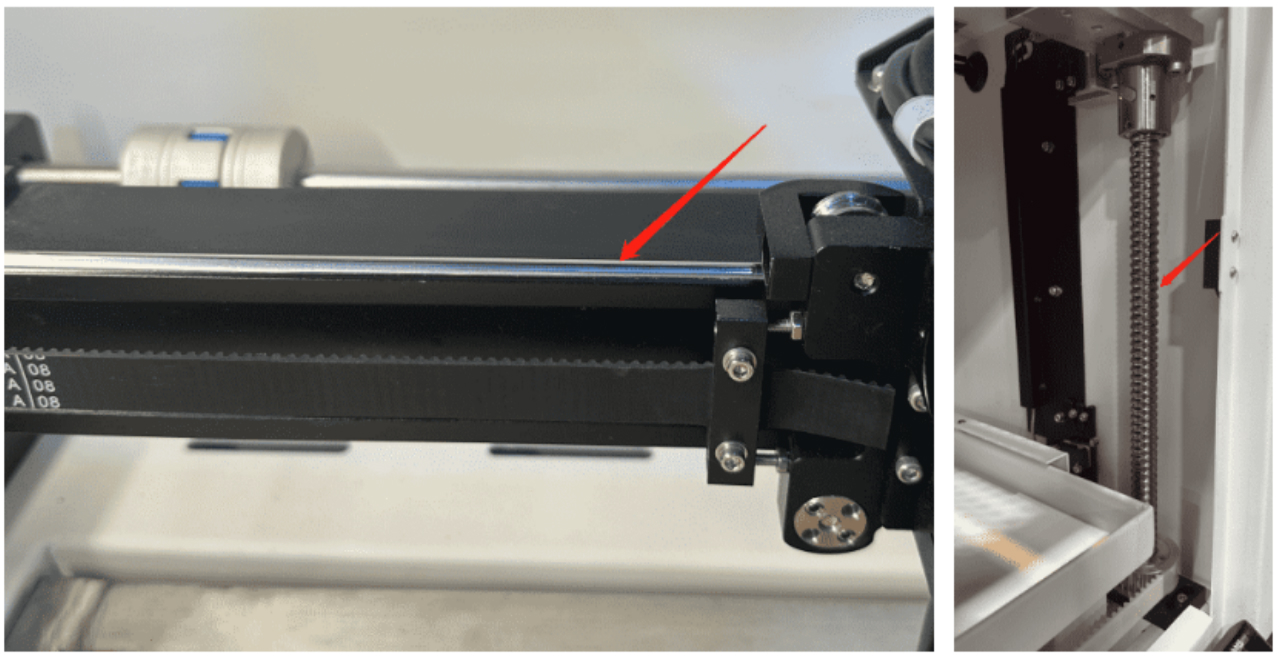

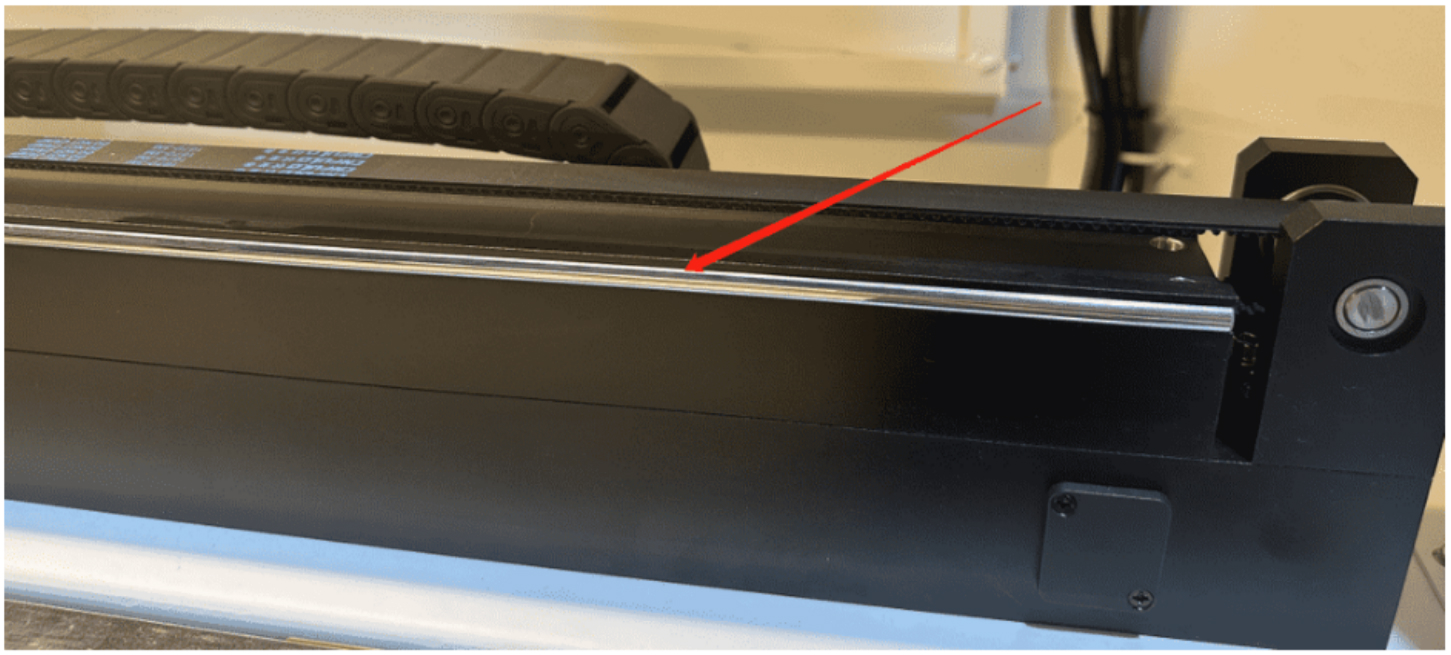

Remove small pieces that fall into the work table, gears, rails, and belts with a small brush or vacuum cleaner.

- Work table

- Gears

- Belt

- Rails

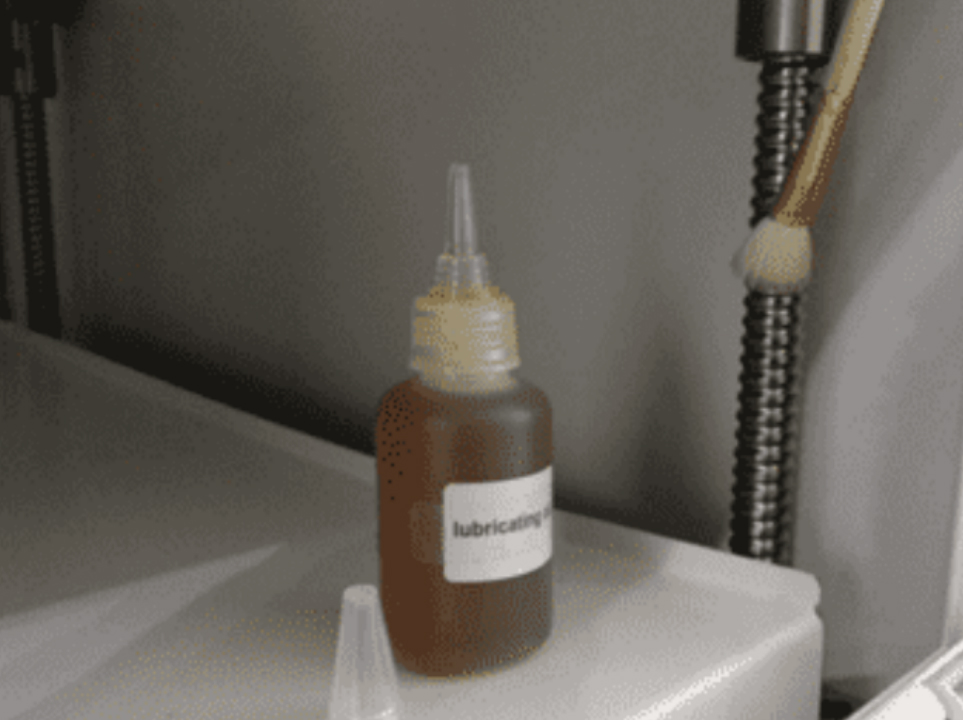

NOTE: Can be maintained with lubricant oil.

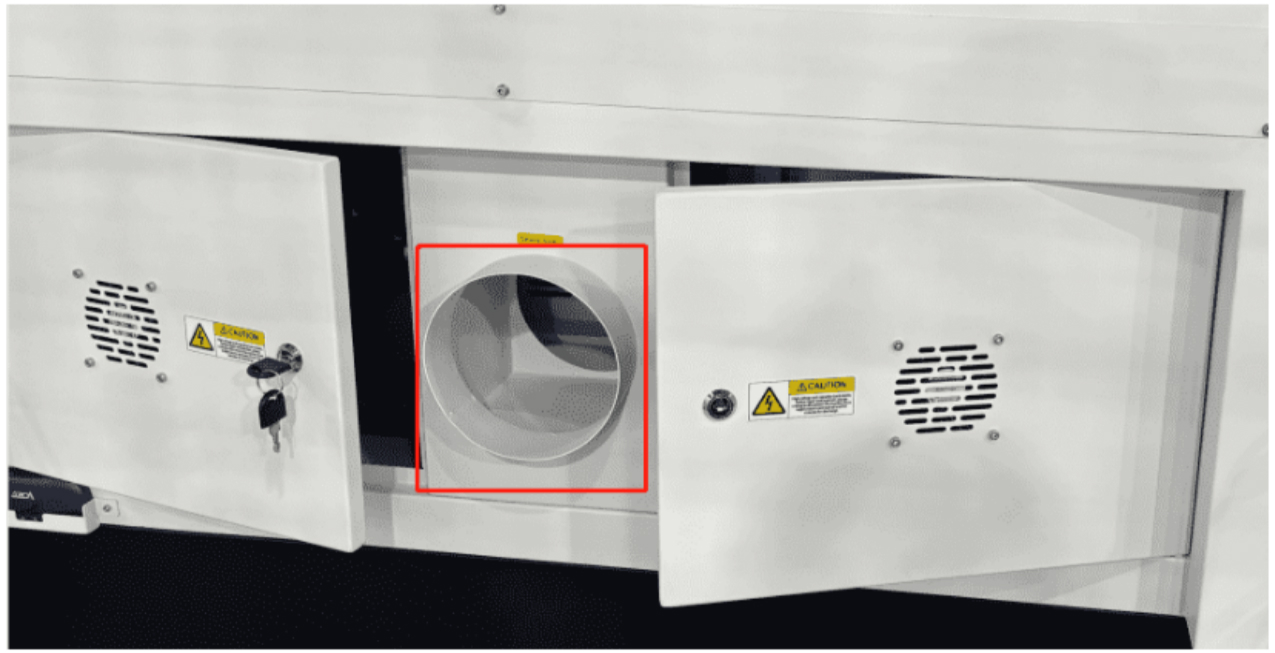

- Exhaust port

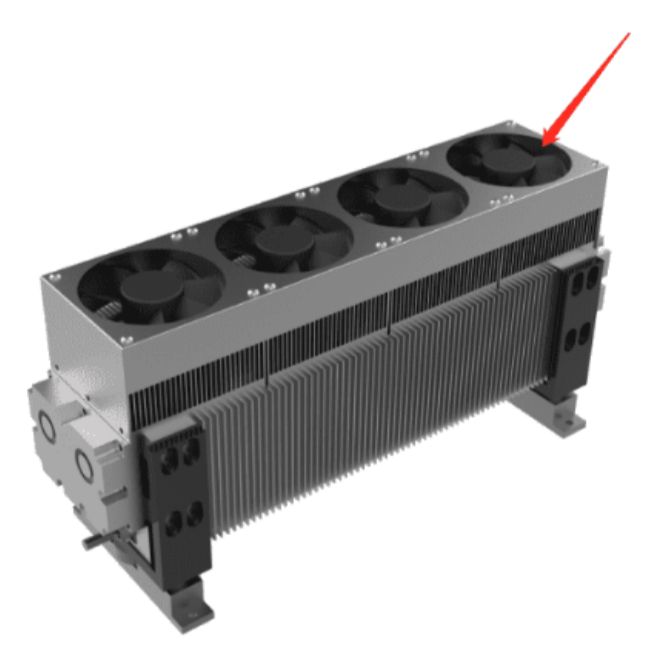

- RF Tube cooling fan

¶ 5.5 Clean the chiller

Change the pure (distilled) water of the chiller every 3 months and clean the filters.

Use the air blow gun to blow away the dust.

¶ 5.6 Clean the exhaust fan

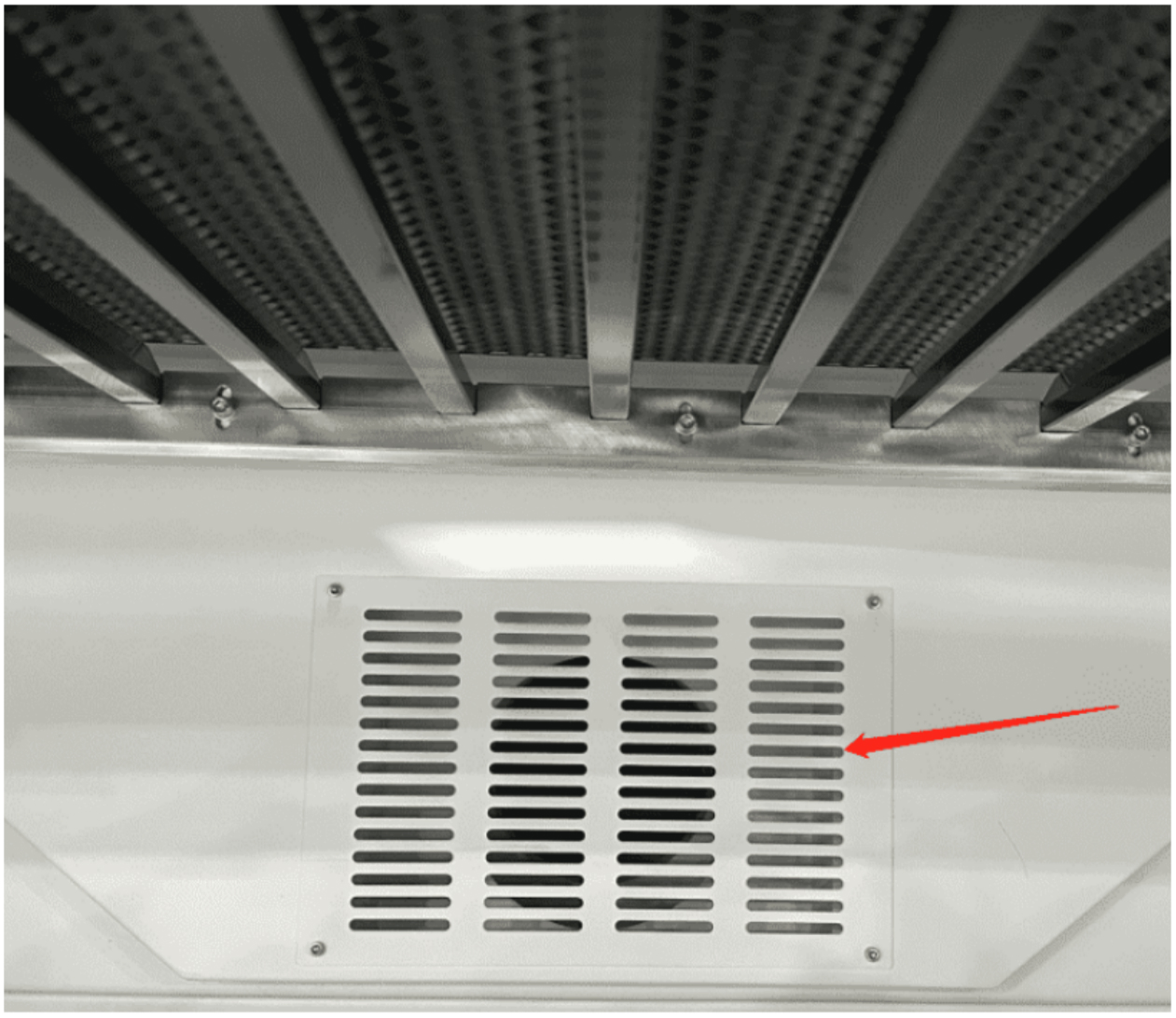

Clean the air intake.

¶ 5.7 Maintenance Plan

Please strictly follow the maintenance instructions in this manual to maintain the equipment. Failure to adhere to these instructions or using incorrect maintenance methods may result in equipment damage, affecting its performance and potentially voiding the warranty.

|

DAILY |

WEEKLY |

3 MONTHS |

6 MONTHS |

12 MONTHS |

|

Lens |

Mirror 2 and 3 |

Mirror 1 |

Belts |

Overall Machine |

|

nozzle |

Work Table |

Exhaust Fan |

Bearing and Rails |

|

|

|

Cooling Fan |

Chiller |

Interior Work Space |

|

|

|

|

Vent Slots(back side of the machine) |

|

|