¶ Process of Installing

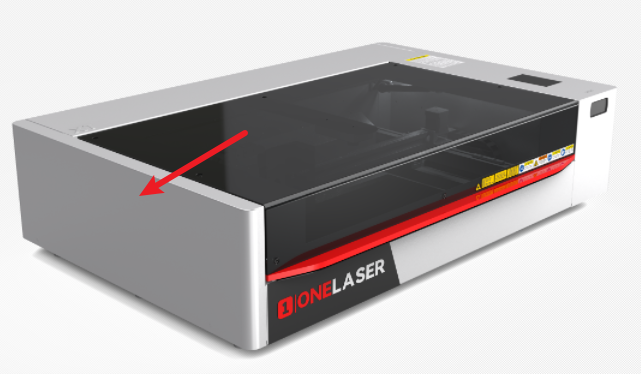

¶ 3.1 Exhaust System – Requirements

Proper fume extraction is imperative to evacuate the combustible and noxious fumes that are created during the lasing process. This machine must be equipped with an adequate exhaust system. This includes a blower of rated flow, volume, and duty cycle as well as properly installed ducting and peripherals. You can further reduce smells from fine particulate matter with an inline filtering system.

.png)

Do not start the machine without an adequate exhaust system.

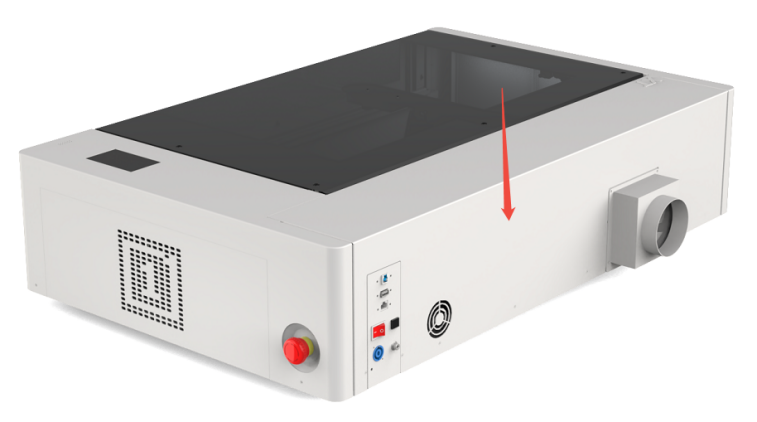

¶ 3.2 Air System – Requirements

The included air pump supplies is a very critical component. This helps keep the focusing lens clean and cool during the engraving process. Air assist is also critical when cutting to reduce flame-ups and clear the debris field.

The air pump is covered by a white metal plate.

.png)

Always use the system’s Air Assist feature when vector cutting.

¶ 3.3 Computer – Requirements

The following recommendation represents the minimum requirements...

¶ 3.4 Connections

Perform the connections exactly in the order described; otherwise electrostatic charging can damage your computer and/or the electronics of the laser system.

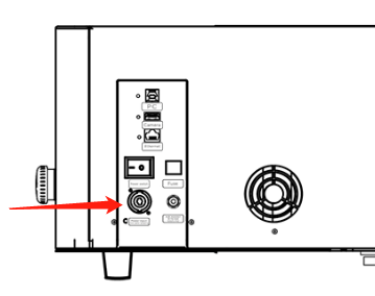

¶ 3.4.1 Connecting the Mains

Connect one end of the mains cable...

Under no circumstances should you switch on the device if the voltages do not correspond.

¶ 3.4.2 Connecting the Cooling System

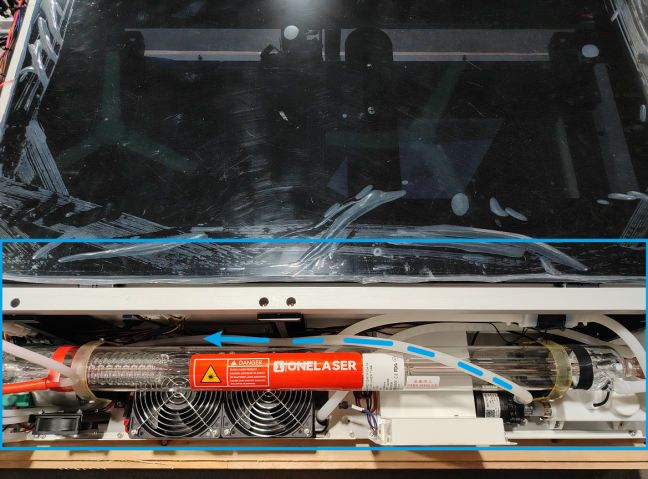

To ensure the normal operation of the One Laser XT model...

① Remove the back cover and left door of the machine...

② Find the location of the chiller.

③ Open the water cover on the top of the chiller and add in about 790ml of pure water.

.png)

.png)

④ After the equipment is turned on, the water in the chiller will flow into the glass tube...

.png)

⑤ After the chiller is filled with water, please reinstall the rear cover and side door of the machine.

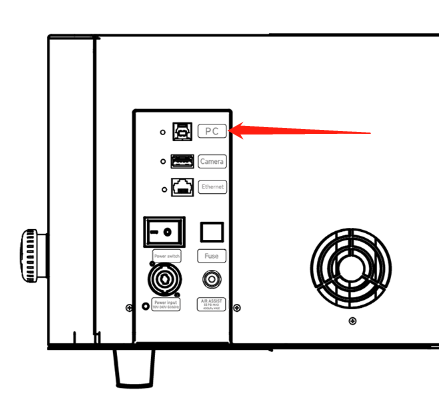

¶ 3.4.3 Connecting the Computer

Connecting the computer and the machine by using the USB cable. Like below:

.png)