¶ X Series Manual - Safety Section

¶ 2.1 General Safety Information

All personnel involved in installation, set-up, operation maintenance and repair of the machine, must have read and understood the Operation Manual and in particular the "Safety" section. The user is recommended to generate company-internal instructions considering the professional qualifications of the personnel employed in each case, and the receipt of the instruction/Operation Manual or the participation at introduction/training should be acknowledged in writing in each case.

Safety-conscious of Working

The machine must only be operated by trained and authorized personnel.

The scopes of competence for the different activities in the scope of operating the machine must be clearly defined and observed, so that under the aspect of safety no unclear questions of competence occur. This applies in particular to activities on the electric equipment, which must only be performed by special experts.

For all activities concerning installation, set-up, start-up, operation, modifications of conditions and methods of operation, maintenance, inspection and repair, the switch-off procedures that may be provided in the Operation Manual must be observed.

Safety Information for the User and/or Operating Personnel

1. No working methods are permitted that affect the safety of the machine.

2. The operator must also ensure that no unauthorized persons work with the machine (e.g. by activating equipment without authorization).

3. It is the duty of the operator, to check the machine before start of work for externally visible damage and defects, and to immediately report changes that appear (including behavior during operation) that affect the safety.

4. The user must provide that the machine is only operated in perfect condition.

5. The user must guarantee the cleanness and accessibility at and around the machine by corresponding instructions and controls.

6. No safety components may be removed or disabled (again we emphasize the imminent dangers, for example severe burns, loss of eyesight, etc.). If the removal of safety components is required during repair and service, the replacement of the safety components must be performed immediately after completion of the service and repair activities.

7. Preparation, retooling, change of work piece, maintenance and repair activities must only performed with equipment switched off and by trained personnel.

8. Any attempt to perform unauthorized modifications and changes to the machine can VOID THE WARRANTY. This does not apply to preventative & general maintenance, adjustment and alignment, etc. that follow OneLaser’s best practices.

¶ 2.2 Laser Safety Information

1. To assess the potential dangers laser systems pose, they are classified into 2 safety classes, OneLaser X Series is a device of class 2. This is guaranteed by the protective housing and the safety installations.

Please note that improper and warranty operation of the device can override the status of Safety class 2 and can cause the emission of harmful radiation.

2. This laser engraving system contains a carbon dioxide (CO2) laser of class 4 that emits intensive and invisible laser radiation. Without safety precautions the direct radiation or even diffuse reflected radiation is dangerous!

3. Without safety precautions, the following risks exist with exposure to laser radiation:

Eyes: Burns to the cornea

Skin: Burns

Clothing: Danger of fire

4. Never try to modify or disassemble the laser and do not try to start up a system that had been modified or disassembled!

5. Dangerous radiation exposure can result from the use of operation or adjustment equipment other than that described here, and if different operational methods are performed.

¶ 2.3 Safety Precautions when Operating the Device

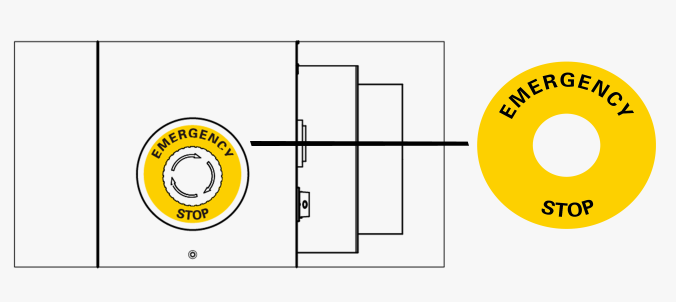

Your OneLaser X SERIES has an integrated safety system which immediately stops the job when the protection cover (Lid) is opened. An incomplete job will occur if the cover is opened during operation. Press the "PAUSE" button first if you want to interrupt an engraving process.

Please remember the following safety precautions when working with this device:

1. CO2 Fire extinguishers should be placed near laser. Always keep a properly maintained and inspected fire extinguisher on hand.

2. Do not store any flammable materials in the inside of the device. Particularly leftovers of produced materials have to be removed to prevent fire hazard.

3. Please maintain free airflow around this system at all times. Do not cover the machine while in operation.

4. Stay with the laser. Do not leave the laser unattended when it is working, small scraps can ignite and without supervision can destroy the machine if not checked.

5. Use Air Assist. Always use the system’s Air Assist feature when vector cutting.

1. These lasers emit invisible radiation; safety glasses should be worn when maintaining these machines for your protection.

2. Adjustment of the beam path must be performed only by specially trained personnel. An improper setting can lead to uncontrolled emission of the laser radiation.

1. Do not disable limit switches or safety features as this can invalidate warranties and cause damage to you and the machine.

2. Before processing materials the user must verify whether harmful materials can be generated and whether the filter equipment of the exhaust system is suitable for the harmful materials. We emphasize that it is the responsibility of the user, to consider the national and regional threshold values for dust, fogs and gases when selecting the filters and the exhaust system. (The values for the maximum workplace concentration must not be exceeded.)

3. PVC (polyvinyl chloride) must under no circumstances be processed with the laser.

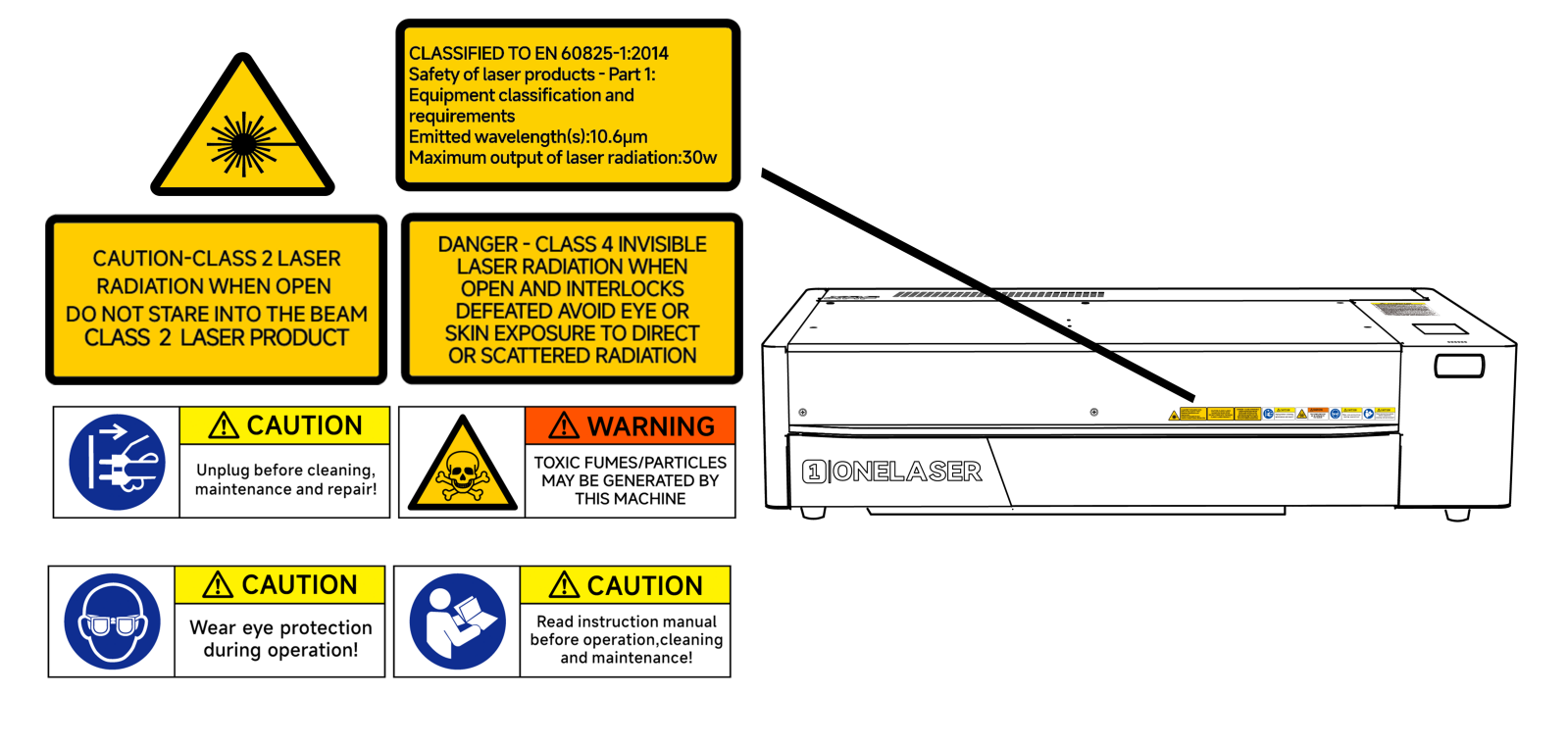

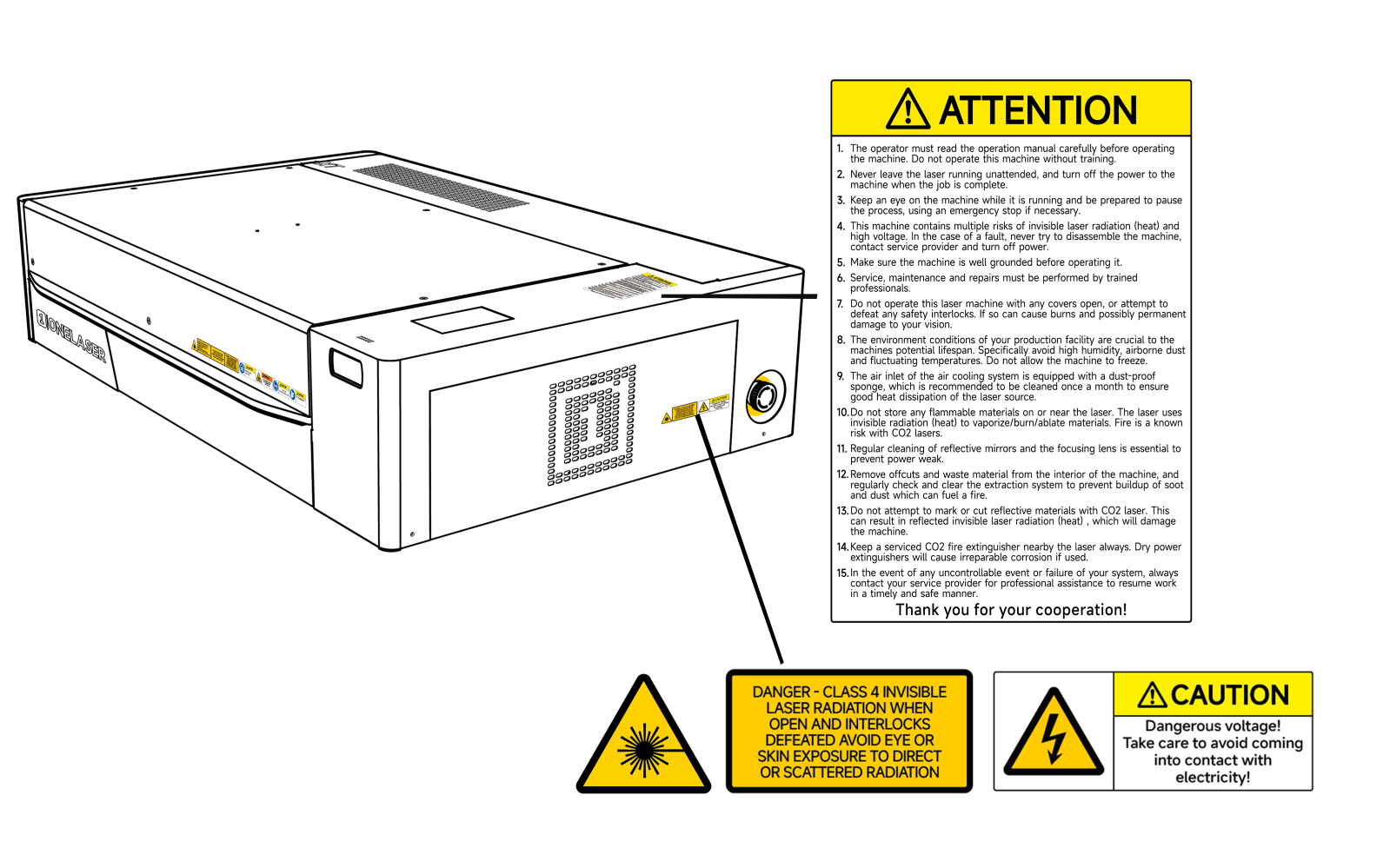

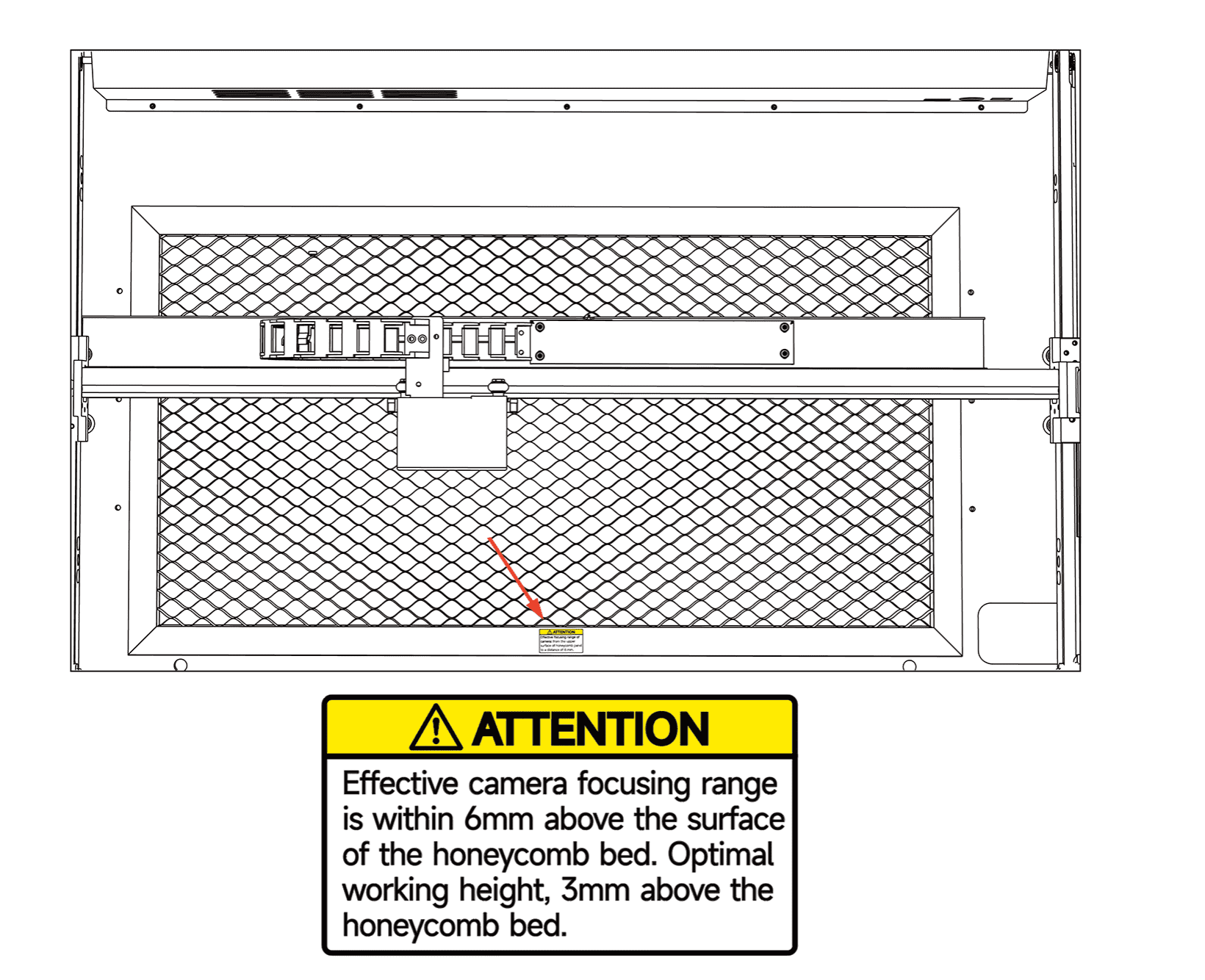

¶ 2.4 Warning and Information Labels

The warning and information labels in various locations if the machine should always be read carefully and understood. If labels are lost or damaged, they must be replaced immediately.