¶ Laser Cooling, Temperature, & Freeze Mitigation

¶ Working environment requirements

CO₂ glass tube laser engraving and cutting machines are sensitive to ambient temperature. Low winter temperatures can adversely affect the normal operation of the equipment. Therefore, appropriate protective measures should be taken to ensure stable performance.

To ensure optimal performance of your laser cutting machine year-round, it's crucial to maintain a suitable storage environment. The room temperature should be between 60°F and 80°F (15°C and 27°C), with a humidity level of 40% to 70%. Avoid exposing the machine to direct sunlight.

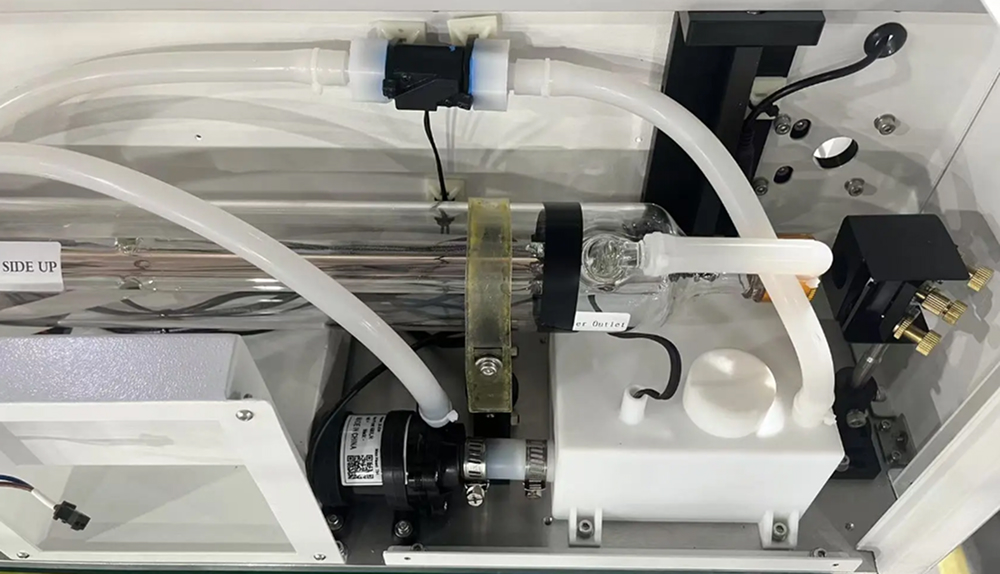

¶ Cooling System

To ensure optimal performance, the operating environment temperature should be maintained between 15°C and 25°C. Extremely low temperatures can cause the coolant to freeze, affecting heat dissipation and potentially damaging the laser tube. Laser machines typically use either air or water cooling, with the specific cooling method depending on the laser model.

¶ Air Cooling

The 1Laser XRF series of lasers utilizes RF tubes as the laser source and employs an air cooling system for heat dissipation.

Air-cooled tubes utilize fans to circulate air over the tube’s heat sinks, facilitating cooling. The system temperature cannot fall below the ambient room temperature. Freezing is typically not a concern due to the absence of water.

¶ Water Cooling

XT series lasers employ water-cooled glass tubes that are susceptible to sub-freezing temperatures. Optimal system operation requires a water temperature range of 15°C to 25°C. If outdoor temperatures fall below freezing, precautionary measures must be taken to prevent laser tube damage. Note that warranty does not cover freezing-related damage.

The chiller must be filled with distilled water or pure water.

¶ Freeze Mitigation

¶ Provide a constant temperature environment for the workspace

Here are some fundamental ways to protect your water-cooled cooling system from freezing:

Maintain operating temperature: Avoid excessively low operating temperatures. Consider using heating equipment if necessary.

Prevent cold air intrusion: Ensure cold air cannot enter the system. If needed, disconnect the exhaust duct from the outdoor environment.

¶ Drain the coolant

In case of a prolonged power outage in winter or when the equipment is idle for an extended period, it is essential to completely drain the coolant from the chiller and its associated piping.

¶ Add antifreeze Coolant

We use pure distilled water in DC-excited glass water-cooled tubes due to its low conductivity, which allows for the safe passage of 30,000 volts of electricity through the tube. Additives can interfere with this conductivity and potentially damage the cooling system components, particularly over extended periods of use.

🔗 OneLaser Approved Antifreeze

¶ Use a water heater

You can actively warm the water up with a water warmer. Be sure to set the temperature setpoint of warm to below the Chiller’s setpoint by at least 2 Degrees Celsius.