¶ Material Cannot Be Cut Through

This guide explains what to do when the material cannot be cut through during laser cutting. It outlines the most common cause—incorrect processing parameters—and provides simple steps to optimize speed and power for a complete and clean cut.

¶ Issue phenomenon

During laser cutting, the material cannot be cut through

¶ Operation Guide

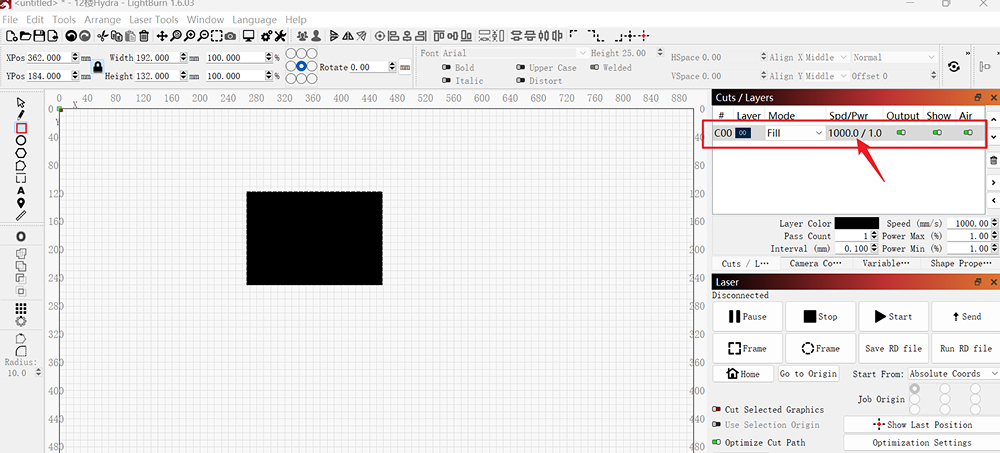

1. Wrong processing parameters

If the speed is too fast and the power is too low, the cutting process will not be thorough.

Please set the correct processing parameters, you can slow down the speed and increase the power.

2. The reflector or focusing mirror is completely damaged.

Failure to maintain the equipment on time may result in the reflector or focusing lens not being able to transmit or reflect light. Check whether the light path reflector and lens have good light transmittance.

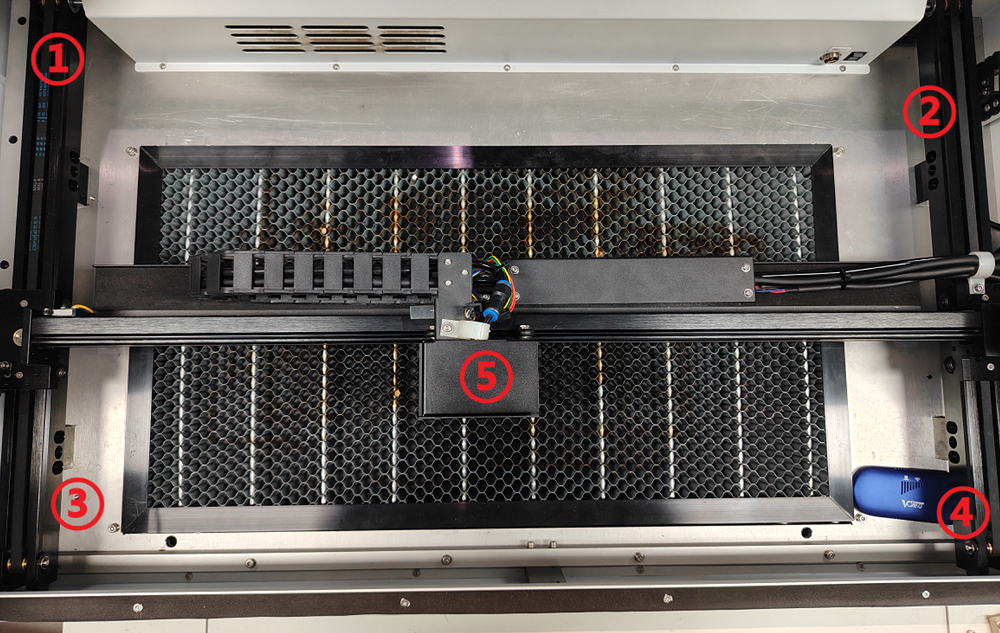

3. Laser optical path deviation

The laser light path is offset, which will cause the laser to hit the inside of the laser head or the inside of the device, and the light cannot be emitted. Please use double-sided tape to stick on the three-mirror frame, and press the point shooting to check whether the light spots of the five light source points in the platform overlap.

If there is an offset, please refer to the “How to adjust the laser light path”

4. Incorrect focus adjustment

The bending of the material itself and the inconsistent height of the working area will cause different focal lengths at different positions in the cutting area, especially when cutting large-format patterns. Please use a strong magnet to flatten the material and use a focusing ruler to check whether the height of each area of the working platform is consistent. If it is not accurate, please use the focusing ruler to readjust the focal length.

5. Laser is weak or damaged

The laser life has reached its limit, resulting in a decrease in light output power

The laser life is usually between 2500–4000 hours, and the specific life depends on the actual operating conditions.